Prioritising the New Design of Fan Coil Units

With a move away from traditional angled or closed coupled fan coil units, we discuss how new unit designs can help to make installation and maintenance easier.

A fan coil system is a decentralized HVAC system with fan coils, or terminal units, at or near the occupied space serviced by central heating and cooling plants.

A fan coil system can be used in many building types including hotels, multi-family residential, offices, schools and office blocks. Fan coils are made up of an enclosure, fan and motor, coil with drain pan and a filter. Fan coils come in a wide range of configurations including the wall, ceiling exposed, horizontal ceiling concealed, stacked and large capacity.

Terminal units heat or cool by using hot water from a central heating plant and chilled water from a central chiller plant. The fan is powered by a small electric motor that circulates room air through the filter and coil. Four pipe fan coil systems have two water loops (hot and chilled water) throughout the building connected to each fan coil. The water loops are insulated thus, providing heating and cooling with water has a very low transportation or pump work cost. As a result, fan coils are an energy-efficient system choice for a range of building types.

However, they are a complex and timely installation for many installers and require a great understanding of the make up of a fan coil unit to ensure that they work effectively.

How can design assist an installer?

Dealing with fan coils and air handling units can be a tough matter without the right equipment. Having a pre-assembled kit for terminal units, which is compact and composed of all devices needed for operation, can help for ease of installation for the installer, as well as quick commissioning and maintenance.

The benefits of pre-assembly

Pre-assembled kits, unlike buying components separately, provide assurance for both the installer and end-user. Through design specification, pre-assembled fan coil units can be custom made to include specific connection types and flow rates in a single assembly. This simplifies the design process for the specifiers, as subsequently saves time for the installer.

Due to the design of pre-assembled kits, with all elements of the kit being readily joined and the kit requiring a minimum number of additional joints, the likelihood of leakages is reduced massively. From this, a cost-benefit can be had, with a reduction in water usage and a reduction in potential maintenance costs.

To further ensure peace of mind, the pre-assembled fan coil units are, often, pre-tested to certify the standard of the fan coil unit. When this is done, the quality and performance of the fan coil unit can be guaranteed, reducing the likelihood of large maintenance costs.

Assured quality and performance

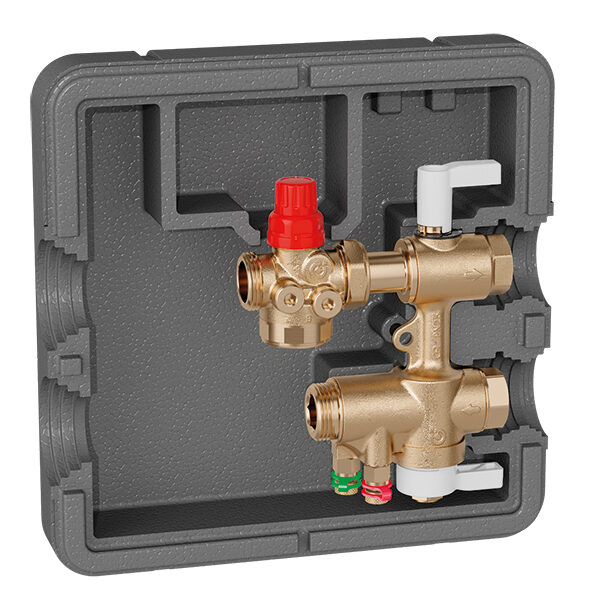

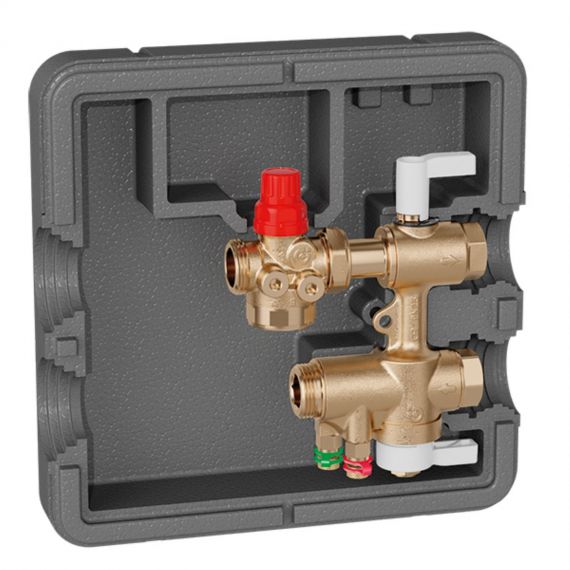

Caleffi offers a pre-assembled fan coil unit- the 149 Series. The linear design of the unit (pictured) allows for quick and easy installation, with the high-quality standard of Caleffi products also incorporated in the componentry in this kit.

Energy efficiency is ensured with this unit as the pre-formed insulation, made of rigid EPP material, prevents condensation issues, whilst also complying with fire regulations.

The dynamic balancing of the system is ensured by Caleffi diaphragm-type PICV 145 series, which can be equipped with an ON/OFF or a modulating 0-10 V actuator. The inner dynamic element can easily be replaced to ensure a long life for the whole assembly.

Caleffi PICV features equal percentage control and full stroke modulation. Furthermore, a unique plus is that the valve does not drop authority even at a setting different than 100% open position, thanks to its special internal configuration.

Two three-way valves allow easy periodic flushing of the system, and an integrated cartridge strainer will protect the terminal unit, to always ensure maximum performance. Such valves can be also used for bypass or isolation of the unit.

A calibrated Venturi flow measurement device will allow an easy and precise commissioning phase, thanks also to the user-friendly setting of Caleffi PICV 145 series.

The multiple-size connections (1/2’’, 3/4‘’, 1”, 1 ¼”) and the huge available range of PICV make Caleffi 149 series suitable for all systems. The possibility of adding flexible hoses increases its universality of installation.

All the levers and ports are installed on the side of the kit to make it symmetrical for universal installation (the kit can be reversed so that it always matches the pipe configuration of the unit).

A step in the right direction

With fan coil units being a step towards energy efficiency, it is of great importance that their installation, maintenance and commissioning are made as easy as possible for the installer.

Caleffi developed the 149 Series just to make the installer’s life easier, whilst keeping Caleffi top-quality standards that are recognised the world over.