Heat Interface Units and Return Temperature Limitation: Optimising Heat Network Performance

Efficient heat networks rely heavily on effective heat transfer and temperature control. One critical factor in achieving optimal performance is managing return temperatures from the system. Heat Interface Units (HIUs) play a pivotal role in this process, with Return Temperature Limitation (RTL) being a key strategy for improving efficiency, reducing energy loss, and ensuring fair distribution of heat across all users. This article explores the role of HIUs in return temperature control, drawing insights from the CIBSE Heat Network Design Guide and the Heat Network Optimisation Guide.

What Are Heat Interface Units (HIUs)?

Heat Interface Units (HIUs) act as the bridge between the communal heat network and individual apartments or buildings. They provide domestic hot water (DHW) and space heating, ensuring users receive the desired heat output while maintaining efficient flow conditions within the network. HIUs can be classified into two types:

- Direct HIUs: Where the network water flows directly into the dwelling's heating system.

- Indirect HIUs: Where a heat exchanger separates the network water from the dwelling’s heating system, providing hydraulic separation.

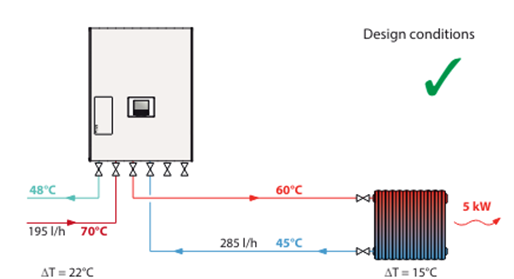

While HIUs efficiently distribute heat, their effectiveness largely depends on the system’s ability to maintain a high delta T (∆T)—the temperature difference between flow and return water. This is where Return Temperature Limitation (RTL) comes into play.

Why Return Temperature Limitation Matters

Return Temperature Limitation is a control strategy designed to ensure that water returning to the heat network remains at an optimal temperature. This approach prevents excessive energy consumption, reduces heat losses, and enhances the overall efficiency of the system. According to the Heat Network Optimisation Guide, system return temperatures should consistently be at least 20°C lower than the flow temperature, with a target delta T of 30°C or more for high-performing networks. The CIBSE Heat Network Design Guide emphasizes the need for proper system design and commissioning to achieve return temperatures below 40°C under all conditions.

RTL acts as a safeguard, ensuring that poorly performing individual systems do not compromise the entire network. It is essential, however, that RTL is not viewed as a substitute for proper system commissioning. Effective commissioning ensures that all tertiary heating systems, emitters, and control valves are set up correctly, allowing RTL to function as an additional safeguard rather than a primary control mechanism.

The correct commissioning of the tertiary heating circuit is essential, RTL is there to help capture instances of high tertiary heating return. The causes of high tertiary heating return temperatures can be varied, effectively, when the emitters have limited capability of transferring heat into the room they serve, for example this could represent itself as placing objects on or close to radiators reducing their ability to emit heat. (probably word this better!)

How HIUs Implement RTL

Heat Interface Units implement RTL through advanced valve technology and flow control mechanisms.

There are specific limits to RTL’s operation:

- In high-temperature mode (45-75°C), the flow change range is 15°C.

- In low-temperature mode (25-45°C), the flow change range is 3°C.

- The heating control valve is deliberately slow-acting to prevent sudden changes and maintain steady performance.

The functionality of RTL ensures that it doesn’t strip too much energy from the dwelling while reducing return temperatures. The goal is to maintain both comfort and system efficiency—a critical balance for effective heating networks.

To illustrate how RTL functions in practice, let's look at the Altecnic SATK32/22 HIU.

The incorrect commissioning of the tertiary heating or indeed objects obstructing the capability of the radiators' ability to transfer heat could cause excessive return temperatures.

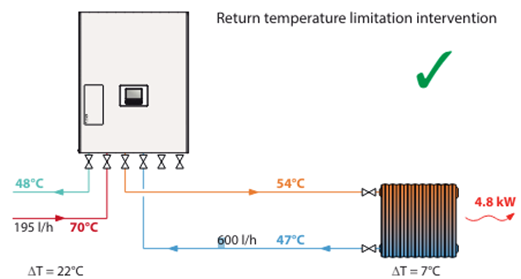

The return temperature control function available in the SATK32/22 heat interface unit provides a useful tool to compensate for high return temperatures. By enabling this function, the SATK32/22 interface will modulate the tertiary heating flow set-point temperature to compensate the high tertiary heating return temperature. This mechanism is deliberately slow acting to ensure the HIU autonomously strikes a perfect equilibrium between comfort and efficiency.

-If T return <= T return, limit then T flow = T flow, set

-If T return > T return, limit then T flow is lowered so as to return T return within the limit set.

The maximum flow rate reduction temperature is 15 °C if the heat interface unit is set at high temperature (flow temperature 45–75 °C), of 3 °C if set at low temperature (25–45 °C).

This example shows that an incorrect balancing creating a flow rate more than twice the design value, e.g. 600 l/h, the HIU would react by reducing the flow temperature to about 54 °C (from the initial 60 °C), restoring the return temperature within the limits (see drawings at the side). It should be noted, however, that this function does not completely replace the hydraulic circuits balancing of the apartment but is designed to compensate for the natural inaccuracies due to practical difficulties.

Conclusion

Heat Interface Units (HIUs) and Return Temperature Limitation (RTL) play a crucial role in enhancing the efficiency of heat networks. By maintaining lower return temperatures, RTL reduces overall energy consumption, improves system reliability, and supports the cost effectiveness of heat to the user. However, its effectiveness relies on proper system design, thorough commissioning, and regular maintenance.

As heat networks continue to expand, integrating HIUs with RTL technology will be essential for achieving high-performance, cost-effective, and environmentally friendly heating solutions. By adopting best practices and leveraging advanced control systems, heat network operators can ensure long-term success while enhancing user satisfaction.

The Altecnic SATK32 HIU exemplifies these best practices, combining advanced electronic controls, intuitive programming, and robust network protection. This ensures that both end-users and heat network operators benefit from lower energy consumption, reduced operational costs, and improved sustainability.